Products

Straight Line Wire Drawing Machine

High speed Straight Line Wire Drawing Machine

Applicable to high/low carbon steel wire, stainless steel wire, non-ferrous metals wire. Mechanical features include the drawing capstan undergoes the hardness spray welding and grinding treatment as well as dynamic balance verification. With internal water cooling and external fan cooling systems; the drawing die base can be drawn out, easy for replacement, and equipped with internal water cooling system; with the protection devices including the safe gate, breaking stop, and emergency stop, the driving gear in the gear box undergoes the high hardness grinding treatment, long in service life and low noise.

Material strength: ≤ 1300MPa

Motor type: frequency type

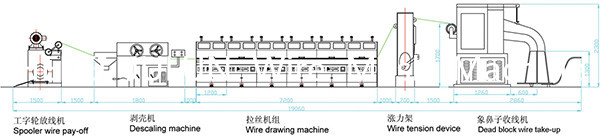

Wire Drawing Production Line:

The full production line includes: pay-off stand----wire descaling machine (pre-treatment)----wire pointing machine----butt welding machine-----wire drawing machine----annealing machine ----spooler take-up

Items | Unit | LZ1200 | LZ900 | LZ800 | LZ700 | LZ600 | LZ560 | LZ500 | LZ450 | LZ400 | LZ350 | LZ300 |

Capstan dia. | mm | 1200 | 900 | 800 | 900 | 600 | 600 | 500 | 450 | 400 | 350 | 300 |

Draw passage | times | 5-9 | 5-9 | 5-9 | 2-9 | 2-12 | 2-12 | 2-11 | 2-11 | 2-11 | 2-11 | 2-11 |

Incoming dia. | mm | 18.0-14.0 | 14.0-9.0 | 12-10 | 10 | 8 | 6.5 | 5.5 | 5 | 4.2 | 3.6 | 2.8 |

Outgoing dia. | mm | 9.0-6.0 | 6.0-4.0 | 3.2-2.2 | 2.2 | 1.6 | 1.3 | 1.2 | 1 | 0.75 | 0.6 | 0.5 |

Total compressibility | % | 82-85 | 82-85 | 82-85 | 82-85 | 84-86 | 84-86 | 89.4 | 90 | 90 | 90 | 90 |

Average compressibility | % | 20 | ||||||||||

Max. Wire drawing speed | m/s | 6 | 7 | 8 | 12 | 12 | 15 | 15 | 16 | 20 | 20 | 25 |

Single motor power | KW | 110-160 | 90-132 | 55-110 | 45-90 | 30-75 | 22-55 | 22-45 | 15-37 | 11-30 | 11-22 | 7.5-18.5 |

Main part of straight wire drawing machine

Capstan material: Based body 45 steel, working surface sprayed with carbonside tungsten alloy powder, hardness above HRC60, surface roughness 3.2Ra. Capstan cooling: internal narrow seam water-cooling (external can use wind force, wear silk)

Transmission system: LZ350-LZ560 wire drawing machine drive through one grade or two grade with a strong narrow V belt smoothly. LZ450-LZ1200 with a powerful drive system which is one grade narrow V belt and one grade hardened gear (vehicle offset spiral bevel gear with) transmission, coincident with high, smooth transmission, low noise; can also use a strong Narrow V belt drive gear box + standard hardened.

The die box: The boxes is lubrication and cooling cavity, using the Hough model (pressure), box can be universal adjustment, die size: for users provide (the common use∮40mm*20mm). Rotary die boxes, pressure mold and mold box mix gray box device are for chosen.

Tuning Device: The tuning roller has a sprayed surface and is wear-resistant, and adopts pneumatic reverse tension tuning with the tension constantly adjustable

Controlling system

1) The main form of control system adopts home-made frequency converter or the brand confirmed by the customer to promise the high accuracy.

2) The secondary circuit use German production S7-300 PLC controller, so the automation degree of machine greatly improve, protection machine fault.

3) Parameters input by the touch screen, the operation is simple, high reliability, drawing process broad, and can be easily realized jump touch drawing

Wire pay off system: Pay-off stand or I-spool pay-off machine

Wire take-up machine:

Main Functions: meter counter: 0.1% tolerance; the machine decelerates automatically at fixed length and stops; it can perform wire breaking detection and stop automatically; any drum joggles positively and negatively and links left and right; all failure information and handling information can be displayed; all movement information is monitored. It supports any die arrangement process, can make compensation automatically through tuning after the die is worn out, which makes it not easy to break the wire. It is provided with a jumper which can cut out drum drawing freely so as to adapt to different processes. It can perform remote control and diagnosis with the backup of the industrial Ethernet according to customers’ requirements.

Safety and Environmental Protection: Adopting a fully enclosed protection system, it has good safety; a dust removing pipeline system can be set to reduce dust pollution according to users’ requirements.

Material Suitable for Drawing: Welding rod; welding wire (gas-protection welding wire, submerged arc welding wire, flux-cored welding wire); steel wire (high, medium and low carbon steel wire, stainless steel wire, pre-stressed steel wire, tyre bead steel wire, rubber tube steel wire, spring steel wire, steel cord, etc.); wire and cable (aluminum-clad steel wire, copper wire, aluminum wire); alloy wire and other metal wire.

Typical Straight line wire drawing machine:

Model | Tensile Strength (Mpa) | Max. inlet wire dia. (mm) | Min. outlet wire dia. (mm) | Speed (m/s) | Motor power (kw) | Application |

LZ11/350 | 1250 | 3.6 | 0.8 | 25 | 22 | Drawing Steel Cord |

LZ6/400 | 1000 | 2.4 | 0.8 | 15 | 11 | Gas-protection Welding Wire Fine Drawing |

LZ8/400 | 1000 | 2.4 | 0.8 | 15 | 11 | Gas-protection Welding Wire Fine Drawing |

LZ10/400 | 500 | 4 | 1.2 | 15 | 11 | Flux-cored Welding Wire Fine drawing |

LZ6/450 | 500 | 5 | 2.6 | 5 | 11 | Flux-cored Welding Wire Fine drawing |

LZ7/560 | 500 | 5.5 | 2 | 10 | 22-30 | Gas-protection Welding Wire Fine Drawing |

LZ13/560 | 1250 | 6.5 | 1.35 | 12 | 37 | Tyre Bead Steel Wire |

LZ9/600 | 1250 | 8 | 2 | 12 | 55 | High Carbon Steel Wire |

LZ6/700 | 1250 | 8 | 2.8 | 8 | 75 | High Carbon Steel Wire |

LZ8/700 | 1250 | 9.5 | 3 | 10 | 75 | Aluminum-clad Steel Wire |

LZ8/750 | 1250 | 10 | 3 | 6 | 75 | High Carbon Steel Wire |

LZ8/900 | 1250 | 13 | 3 | 5 | 90 | Pre-stressed Steel Wire |

LZ9/1200 | 1250 | 16 | 3 | 6 | 110 | Pre-stressed Steel Wire |

The Finished Products (Wire)